Due to the several questions from Ellebogen users, we make an article to explain the reasons why the propeller shaft has to be fixed 48 hours after the installation of the marine engine mounts.

Vibrations on a marine engine can occur for several reasons or origins, engine unbalance, incorrect stiffness of flexible engine mounts, wear of the marine engine mounts, misalignment of the propeller shaft or a combination of them. On the below video correctly aligned engine with new mounts is shown. The difference is very clear.

On Yanmar, volvo, Mercury, Beta marine or other marine engine engine brands, the predominant frequency is caused by the firing order. The firing order is equal to the number of cylinders divided by 2. This is to say, if we are talking of a 4 cyl engine, for example: 4JH2BE , 4JH2TBE, 4JH2HTE, 4JH2DTE, 4JH2UTBE, 4JH2UTE engines, then we should expect that the firing order is the number 2 (4/2). This is to say the predominant frequency is the crankshaft rotation multiplied by a factor of 2.

If we do a vibration measurement on the engine and we observe the predominant vibration frequency is equal to the crankshaft rotation, then we are facing most likely a vibration originated by the proper misalignment of the propeller shaft. Since the frequency is lower than the firing order, it is close from the natural frequencies of the engine suspension and we often have a case of resonance or simply a situation with forced vibrations.

That is why special care has to be taken to the correct alignment of the propeller shaft. (video of the process of alignment can be found here: https://youtu.be/q6dVSgNTFn0

One of the points that can be seen on the video is propeller shaft alignment after 48h from the installation of the marine engine mounts.

The reasons why this has to be done is coming from the inherent properties of the elastomer used on the mounts. More precisely, due to the creeping of the rubber.

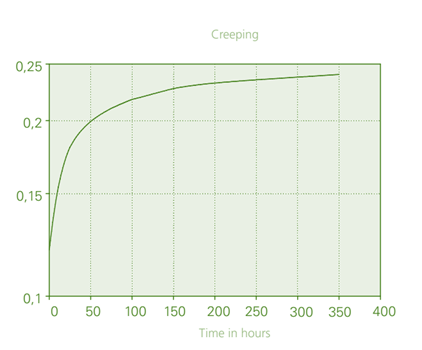

All elastomers, no matter the hardness or type of rubber suffer a “set” during the first hours of installation. Creep refers to the additional deformation of rubber under a constant load.

Creeping has a predictable behaviour, where the majority of it happens during the first 48h

This “settlement” of the deflection of the marine engine mount has to be considered when fixing the propeller shaft. Once the engine mount has his deflection stabilized, then is the moment to fix it to the shaft. When we do not do that, we are exposing ourselves to a misalignment that will not allow us to obtain the best results from the new engine mounts.

This is something that happens always, no matter if the engines are the 2YM15, 3YM20, 3YM30, 2GM20, 2GM20F, 3GM30, 3GM30F, 3JH2BE, 3JH2TBE, 3JH2TE, 4JH2BE , 4JH2TBE, 4JH2HTE, 4JH2DTE, 4JH2UTBE or 4JH2UTE.

Do not hesitate to contact Ellebogen if you have questions. You can easily contact us by clicking on this link.